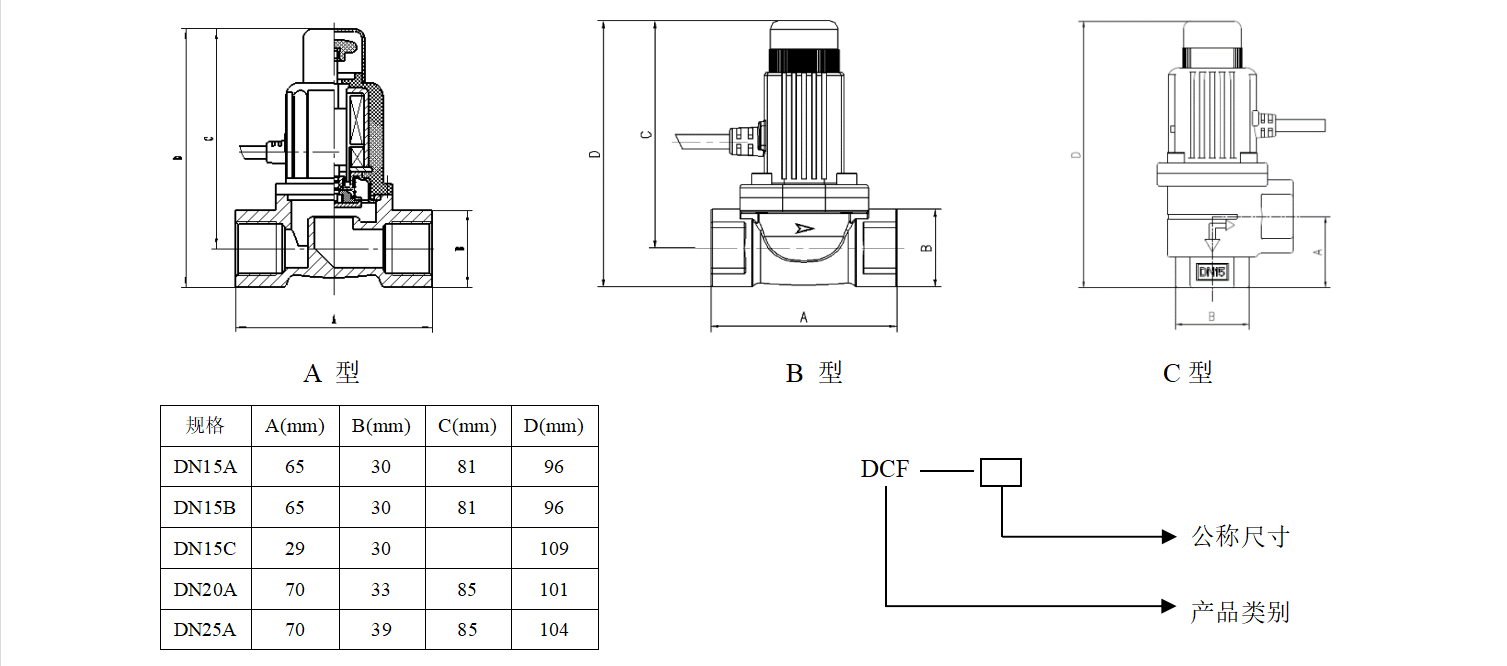

Home-DN15C type valve A

Gas solenoid valve manual

I. Overview:

The company's TNDA series gas solenoid valve is a safety emergency shut-off device for gas pipelines. It can be connected to a gas leak alarm system or to fire control and other intelligent alarm control terminal modules, etc., to realize on-site or remote automatic / manual emergency shutdown of the gas source to ensure gas safety. This product has fast cut-off function, good sealing performance, low power consumption, high sensitivity, reliable operation, small size, easy to use, etc. Valve opening must be manually intervened and manually opened to meet safety management specifications and meet the characteristics of accident handling.

I. Main technical parameters:

1. Applicable gas: natural gas; petroleum liquefied gas; artificial gas and other non-corrosive gases.

2. Valve closing mode: DC pulse drive / manual.

3. Static working current: 0A; power consumption: 0.5W ~ 2W .

4. Drive current: <1.5A (pulse).

5. Output mode: normally open.

6. Coil resistance: 13.5 ± 0.5 Ω .

7. Valve opening mode: manual reset.

8. Connection method: DN15 is G1 / 2 , DN20 is G3 / 4 , and DN25 is 1 ″ thread.

9. Driving voltage: DC9V ~ DC12V .

10. Cut-off time: <0.3 seconds.

11. Path: DN15 / DN20 / DN25 .

12. Working temperature: -1 0 [deg.] C - . 6 0 [deg.] C .

13. Relative humidity: ≤ 93% .

14. Maximum working pressure: A type / ≤ 100k P a ; B type ≤ 50k P a; C type ≤ 10k P a

15. Explosion-proof type: Pouring type.

16. Explosion-proof mark: Ex mbⅡBT6Gb.

17. Implementation standards: GB3836.1-2010, GB3836.9-2 014 and Q / 09526386-5 · 1 —201 4 .

18. Outlet length: 0.35-1 meters.

19. Valve body material: aluminum alloy, copper alloy.

20. Sealing material: Ding Qing rubber.

3. Principle:

The solenoid valve cleverly utilizes the interaction of the instantaneous electromagnetic force of the coil with the permanent magnet force and the spring force to realize the functions of pulse-driven automatic holding and closing and manual opening and self-holding.

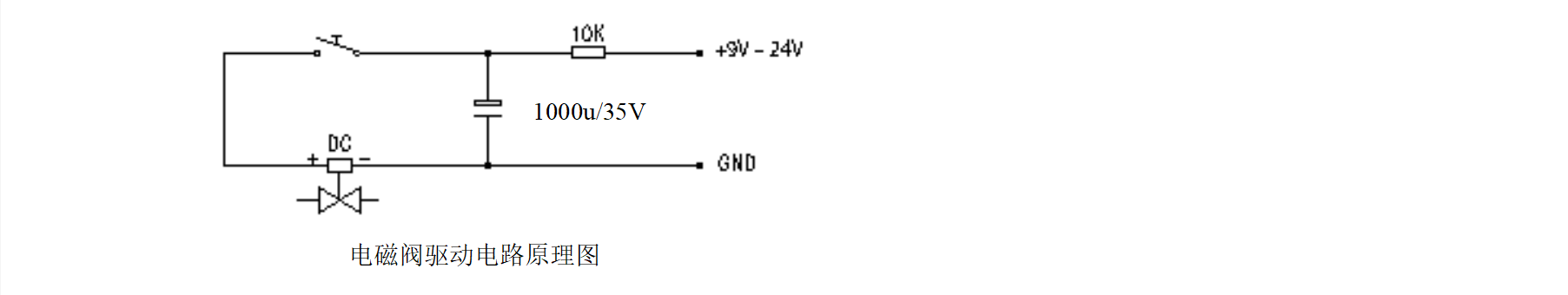

Valve closing driving principle: instantaneous DC pulse driving valve closing (DC9V ~ DV12V / ls)

Example: Schematic diagram of capacitor discharge mode drive circuit:

Fourth, the operating instructions:

1. There are two ways to close the valve when the valve is open:

a) to provide a solenoid (approx . 1 second) transient current pulse ( the DC. 9 - 12V ) power, the quick closing of the valve;

b) The valve can be closed by manually pressing down the red handle.

2. There is only one way to open the valve in the closed state: manually pull up the red handle to open the valve.

Note: When opening the valve, if it is difficult to pull up the handle, measures should be taken to balance the inlet and outlet pressures at both ends of the valve, and then open the valve after balancing. Avoid brutal operation, so as not to damage the valve opening actuator.

3. The valve is in the open state: Due to the design of the magnetic lock principle, the valve may close automatically when it encounters harmful strong vibrations, which is normal. If the valve opening self-locking force is abnormal (too small), the manufacturer should be notified for repair.

4. After the valve is cut off urgently, it must be confirmed on the spot manually, and the hidden danger of the accident can be manually reset and ventilation can be restored.

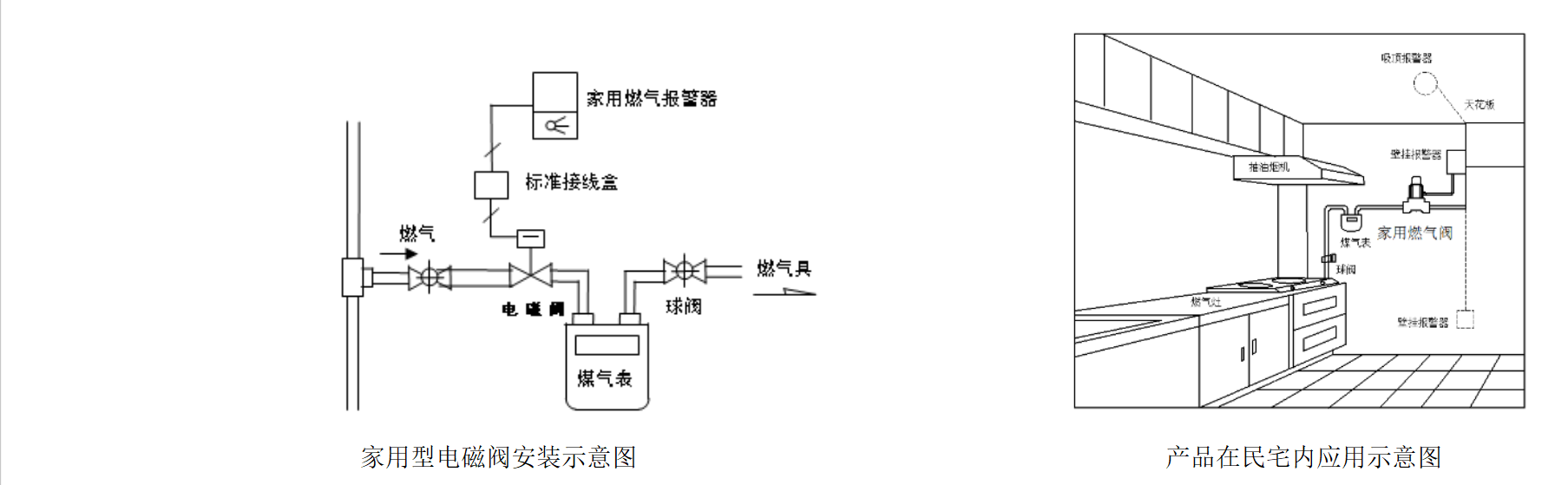

Five, installation requirements:

1. Valve installation units shall have corresponding qualifications and be installed in accordance with relevant gas pipeline construction specifications.

2. The valve should be installed after the main inlet valve in the house for maintenance.

3. It should be installed in the direction of air flow indicated by the valve body. The valve body coil must not be upside down, allowing horizontal and vertical installation.

4. The solenoid valve control wire should be connected correctly and reliably. The control wire has polarity: the red wire is positive, and the black wire is negative.

5. When the pipeline is purged, it is recommended to isolate the solenoid valve to prevent the debris in the pipe from damaging the valve sealing material.

6. Before conducting pressure test to check the sealing performance of the pipeline, the solenoid valve should be opened.

7. When opening the valve manually, it should be operated when the pressure at the inlet and outlet of the valve is balanced.

8. When the valve is electrically closed, do not connect it to the wrong power source, such as: wrong polarity, wrong voltage or long time power on, so as not to damage the electromagnetic coil.

9. Any valve damage or component loss caused by improper storage or illegal construction is not covered by our free warranty.

Six home-based emergency shut-off solenoid valve installation instructions

Seven, wiring requirements :

1. Cable: It is recommended to use double-core protective conductor 2 × 0.3 mm 2 , and the terminal is to be inserted in the wiring. Wiring distance: The wiring length is less than 20 meters.

2. Connection form with household alarm:

1) Insertion: The outlet terminal of the solenoid valve and the inlet terminal of the household alarm can be directly inserted, but the models of the two terminals must be consistent.

2) Welding: The outlet of household alarm and solenoid valve is directly connected by soldering.

3) Cold pressure: The household alarm and the solenoid valve are connected after the cold pressure terminal.

Eight, valve maintenance:

It is recommended that users regularly check the valve for opening and closing. If any failure is found, the professional or manufacturer should be notified in time for maintenance.

Nine, quality assurance

Chengdu Tenda Gas Equipment Co., Ltd. (hereinafter referred to as Tenda) products are strictly inspected before they leave the factory and meet the relevant national standards or industry standards.

Chengdu Tenda Gas Equipment Co., Ltd. promises that every customer who purchases a Tenda product will have a free replacement if there is a quality problem within one year from the date of purchase of the product. Products that are damaged or missing due to the following conditions are not eligible for this free replacement service:

1. Negligence, accident, disaster, improper installation and use;

2. Unauthorized disassembly and modification of the product;

3. Damage caused by the transportation process; (negotiated with the freight carrier)

4. Materials or defects in design and manufacturing that cannot be found at the scientific and technological level when the product is put into circulation.

10. Limitation of Liability

1. The user should acknowledge that the product itself has determined the purpose and suitability of purchasing it, and Ternda is not responsible for the consequences of the recommendations provided.

2. Tenda is not responsible for the loss caused by the use and maintenance of the product not strictly in accordance with the requirements of this product manual.

3. Any problems caused by the use and maintenance of products by non-qualified personnel, or unauthorized changes or replacement of internal parts, will not be held responsible.

This product manual is published by Tenda. Due to typographical errors or continuous product updates, the content of this manual may differ from the actual product. These changes are subject to change without notice. For the latest version, please call our company.

Tel: 028-84828756. Fax: 028-84828756. Chengdu Teanda Gas Equipment Co., Ltd. reserves the right of final interpretation .